Heat Pump Water Heaters

Heat pump water heater systems generate the energy content of a heat source, which for the most part is surrounding air, to produce hot water very efficiently. Although depending on cold water and ambient air temperatures and on hot water usage the Voltex will do the same job as an electric water heater but uses less than half the energy source.

(Figure 1) The compressor pumps a refrigerant through an evaporator, raising its pressure until it liquefies in the condenser. This process heats up the condenser and cools the evaporator as air passes through it gathers heat from the air. The Voltex Cools and dehumidifiers the air that passes through the condenser, which is very nice because in humid or warm spaces like garages or basements it's a benefit.

Efficiencies

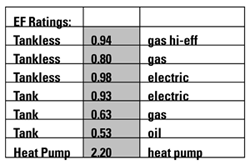

Heat pump water heaters rely indexes of energy efficiency: coefficient of performance (cop) which is favored by the manufactures relating to energy factor (ef) which is used by manufacturers of residential heat pump water heater systems. In both cases a higher value indicates greater efficiency.

COP is a measurement of energy output of a system in comparison with its energy input. Standby losses and the interaction of changing water and air temperature are not reflected in measurements of COP. Examples: the COP of a standard electric hot water heater is close to 1 and a COP of a typical heat pump water heater can be as high as 3.

Energy factor is a more useful measurement because it reflects circumstances that are likely to occur in the field. The test to determine EF is conducted over a 24 hour period with temperatures of incoming water and input air held constant. They measured amount of water is pulled from the system every other hour for the first 12 hours or more and no water is drawn for the final 12 hours.

These tests also reflect standby losses, the EF of a typical electric water year it is 0.90 and the EF of a typical heat pump water anywhere from 2.0 to 2.50. This represents an efficiency improvement of more than 200% or more even ignoring the cooling benefits and dehumidification.

Picture of a system

figure 1: the heat pump cycle

What are the options? And who's the best

Now there are a variety of heat pump water heaters on the market today from small residential versions to large commercial systems that can produce more than 3000 gallons per hour of hot water and over 30 tons of air conditioning.

Here we are only dealing with residential and we will tell you in our opinion who has the best equipment and options on the market today.

A Let's look at what they call add-on units these units are heat pumps that are very small like the size of a small air conditioner and can be either install on top of a existing water heater or can be put on a shelf or the floor.

We do not recommend these units because of their notoriety of having problems with their systems and some are not certified.

Integrated systems incorporate both a heat pump apparatus and the water tank into a single unit which most of the time are on top. Most of these systems are called "drop-in" systems because they are all one unit. They are more compact than add-on systems and they tend to have the same footprint as an ordinary electric or gas water heater.

Make the best choice

US Heat Pump Manufacturers for residential use.

A/O Smith Corp. integrated model 60 gallon or 80 gallon.

Reem Corp. integrated model 50 gallon

General Electric Corp. integrated model 50 gallon

Stiebel Eltron Corp. integrated model 80 gallon

Our recommended choice of all of these units would be the A.O. Smith "Voltex" because of its superiority in the way it's built the energy factors are high and the quality is impressive.

It has the highest annual savings of any integrated heat pump water heater on the market today!

Consumer Reports also rates to be one of the best.

The Voltex also has some impressive features like a powered anode to protect the tank from corrosion and eliminating the service requirements of a conventional water heater. It has a very nice electronic user interface with very friendly controls in plain English and intuitive icons provide easy interaction. Child resistant safety locks backlit mode buttons are among other features.

The Voltex also has an environmentally friendly R13a refrigerant. It is a UL listed product and has Energy Star Certification.

The Voltex will pay for itself in four to five years depending upon energy rates and water usage. There is no other water heater whether to be tank-less or even solar that can pay for itself like this. Let's give an example the average solar system installed cost between $6,500 to $12,000. It could take up to 15 years to pay for the system and they could lack efficiency when install.

Tank-less water heaters, if you were to install an electric tank-less heater by the time you pay for the heater and the electrical service installation to operate this could cost you anywhere from $3000-$10000 depending on demand. Thankless water heaters have a higher maintenance rate especially with well water or water that has heavy lime content runs through the system. The tank was water heater can get clogged up and operate inefficiently causing low water pressure and more maintenance thus spending more money.

The Voltex in our opinion is the best water heating product because not only does it save you money on your electric bill but it also dehumidifiers and cools the area that it's in and virtually has no maintenance other than periodic flushing and filter cleaning.

Heat Pump Water Heater Information

Step right up! Get your tax credits here! Well, at least up until Dec. 31, 2010. Due to expire at the stroke of midnight, the 30% up to a maximum of $1,500 Federal tax credit, has been a boon for business these past two years and a huge advantage for selling tax-credit-eligible products. With less than half a year to go, we'll need to sharpen our sales skills if continued sales of more expensive, higher-efficiency equipment are to continue at, or near to, the same pace.

One of the newer products available for heating domestic hot water is the concept of adding a small heat pump to pluck BTUs from the surrounding air and transfer them to the tank's water. The "magic" of the refrigerant compression cycle allows for greatly enhanced efficiency when compared to an electric-resistance-only water heater. As with all water heaters, heat pump models are also assigned an EF (Energy Factor) that can be used to project operating costs. Operating costs, once accurately projected, give you a powerful sales tool for calculating ROI and/or simple payback over an extended timeframe.

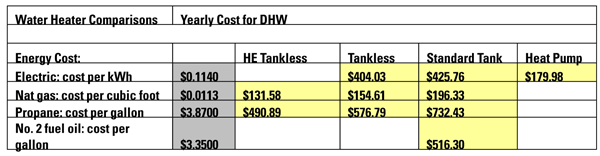

Base calculation information is required. For this example, the average incoming cold-water temperature will be 55ºF, target storage temperature is set for 120ºF, and the daily use of hot water is 60 gallons. This results in a net input of 541.45 BTUs per gallon, or 32,487 BTUs net input per day. At this point, you can begin to run yearly cost projections by incorporating water heater manufacturers’ EF-ratings, local fuel costs and BTU-ratings for fuel. The additional information below is used to nail down the final operating cost.

The formula looks like this: ((net energy input required ÷ (BTU energy per unit x EF)) x cost per unit of fuel ÷ 1,000) x 365 days = operating cost.

If we apply that to a heat pump water heater with an EF of 2.2, the numbers are as follows: ((32,487 ÷ (3.414-BTUs per W x 2.2)) x $0.114 per kWh ÷ 1,000) x 365 = $179.98.

Let's change that to the customer's existing .93 EF electric-resistance model: ((32,487 ÷ (3.414-BTUs per W x .93)) x $0.114 per kWh ÷ 1,000) x 365 = $425.76.

The heat pump model will, if allowed to operate in its most efficient mode (more on this next month), save your customer $245.78. We're going to have deregulation in 2011 with a projected increase of 37% to $0.156 per kWh. That results in the following: electric-resistance tank, $582.61; heat pump tank, $246.29; and a projected savings of $336.32. As costs for fuel rise, so do the savings, which helps make the higher-cost, energy-efficient model more attractive. Let's gussy her up a bit more!

Assume it costs $950 to install a 50-gallon electric-resistance model and $2,950 for the 50-gallon heat pump model. The cost difference is $2,000. The 30% Federal tax credit would reduce that cost difference to $1,115. The ROI is calculated by dividing the cost difference into the cost savings:

Cost savings (first year) of $245.78 ÷ $1,115 = .2204 x 100 = 22.04% ROI, which in this economy beats both the stock market and real estate as an investment.

Cost savings (second year) – no tax credits – of $336.32 ÷ $2,000 = .1682 x 100 = 16.82%, and that too is a rock-solid number for any investment.

As fuel costs rise, and they will, the ROI gets better and that’s when we can begin to project simple payback. At first-glance, the simple payback looks like a simple division equation: divide the savings into the cost difference to determine years. We know the second year savings after deregulation will be $336.32, so $2,000 ÷ 336.32 = 5.9 years. By including the 5% per year increase in fuel costs, the actual payback occurs two months earlier and if we run the calculations for 13 years, we see the following:

Cost to operate electric-resistance model = $9,699.24 Cost to operate heat-pump model = $4,100.21 Savings = $5,599.03

So, you might wonder, how does a heat pump water heater stack up against other types of water heaters using these same household hot-water-usage assumptions? Selling without the tax credits can be done if we present our customers with the information they need to clearly see the financial benefits beyond up-front pricing roadblocks that blind them to reality. Believe in what you sell — sell what you believe in.

r heater information and technical

- How Can I Keep My Toilet Bowl Clean? ()The two things that are the biggest waste of money are bleach tablets and blue dye cleaners.These two products are the worst thing in the world for your toilet bowl, because they don't work. The ... [more]

- Slab Leaks... What is a Slab Leak? ()Slab leaks, sometimes customers ask, what is a slab leak. The term slab leak is used primarily in the southern United States, by all plumbing contractors. This terminology represents leakage on a ... [more]